GAINESVILLE, Fla. — Engineers at the University of Florida have been pushing to produce low-cost, easy access ventilators to serve as a backup option during a shortage in the coronavirus pandemic.

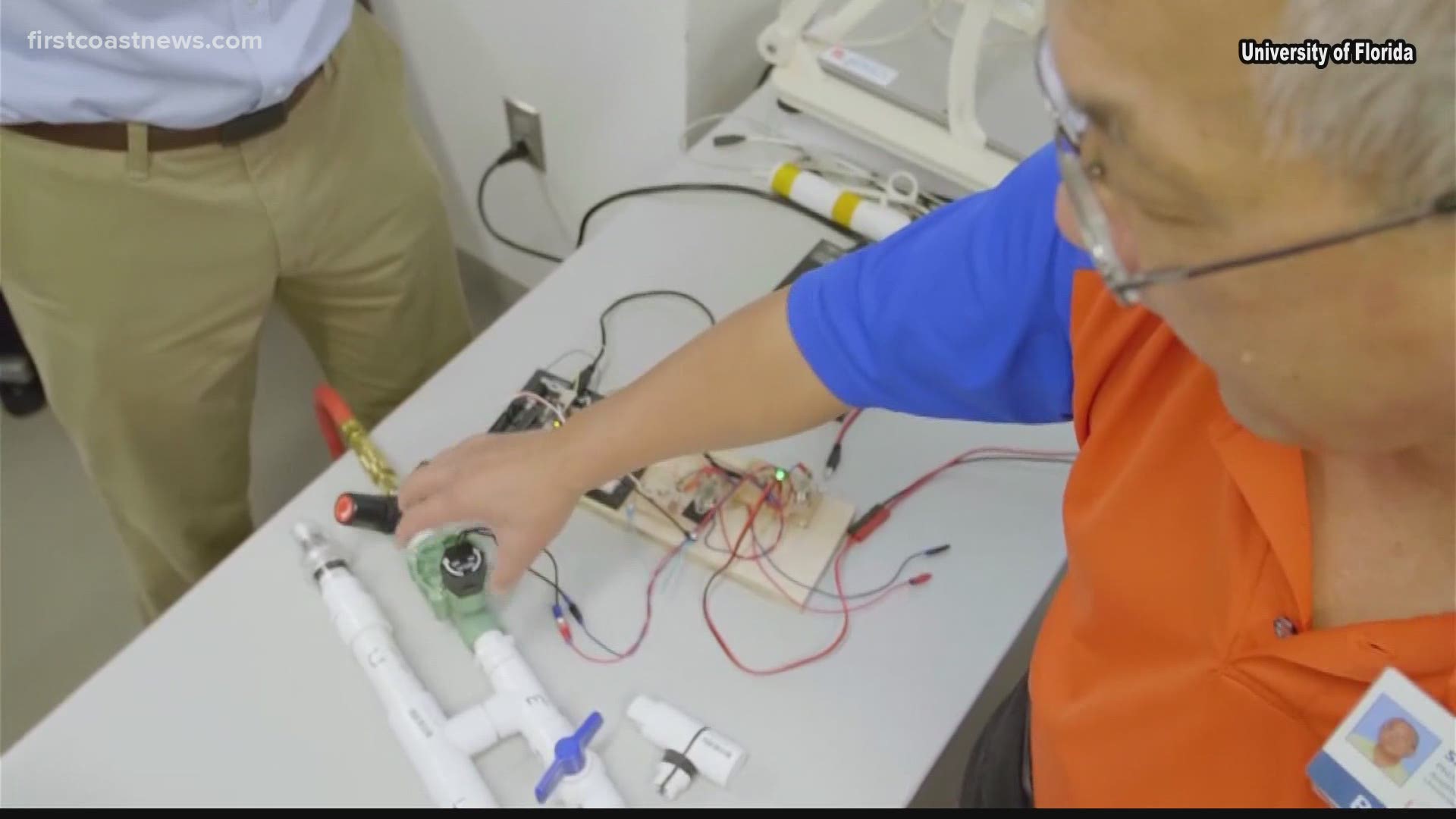

“We are using parts that are available outside the ventilator supplies chain,” said Professor Samsun Lampotang, who has been leading the team creating these ventilators.

The team is using parts like PVC pipes and lawn irrigation valves.

“The main idea was we’re not trying to interfere with what GM and Ford are trying to do,” Lampotang said. “So we should let them have the parts to build the full feature ventilators.”

The homemade ventilator adds up to about $250, compared to a typical ventilator that could cost tens of thousands of dollars. It also takes about three hours to be made by one person.

“We want to be there as a backup,” Lampotang said. “And if our design is never used, we are very happy with that because that’s good news, right? But if it’s needed we want to be there.”

Lampotang’s ventilator has supported a set of artificial lungs for about four weeks now.

Lampotang said he has no doubt this design is ready, the team is just awaiting FDA approval.

“I’ve built a ventilator before,” Lampotang said. “It’s not like it’s my first. I just substituted the ingredients.”

Now by all means, Lampotang says this isn’t supposed to replace our typical ventilators, it is only meant to be a backup plan in a ventilator shortage. Lampotang said this design may have a future in countries that normally have a ventilator shortage.

“Necessity is the mother of invention,” Lampotang said.